Precision Part and Tool Design/Build

Molds , Dies , Fixtures , and Tools... Design and tooling to fit your specific requirements

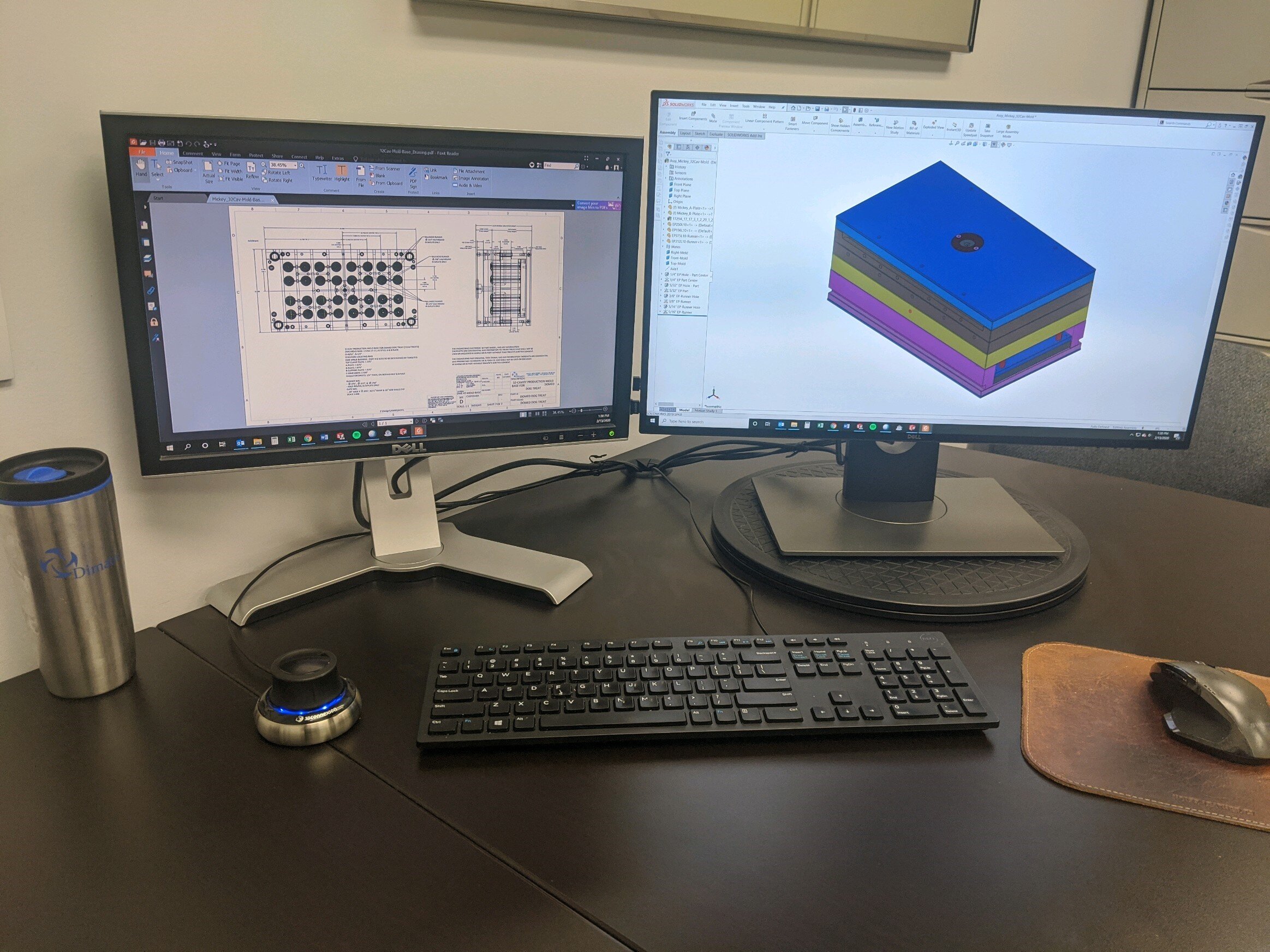

Part and Tooling Design

Full part design and/or assistance to improve your part's structural, cosmetic, and cost-efficiency requirements

Use of ProEngineer® state of-the-art software providing full three dimensional solid modeling

Full mold, die, and fixture design for your approval

University degreed engineers providing years of design expertise

Ability to provide 3-D printed prototype models

Engineering feedback with molding /stamping departments to continually improve design and production processes

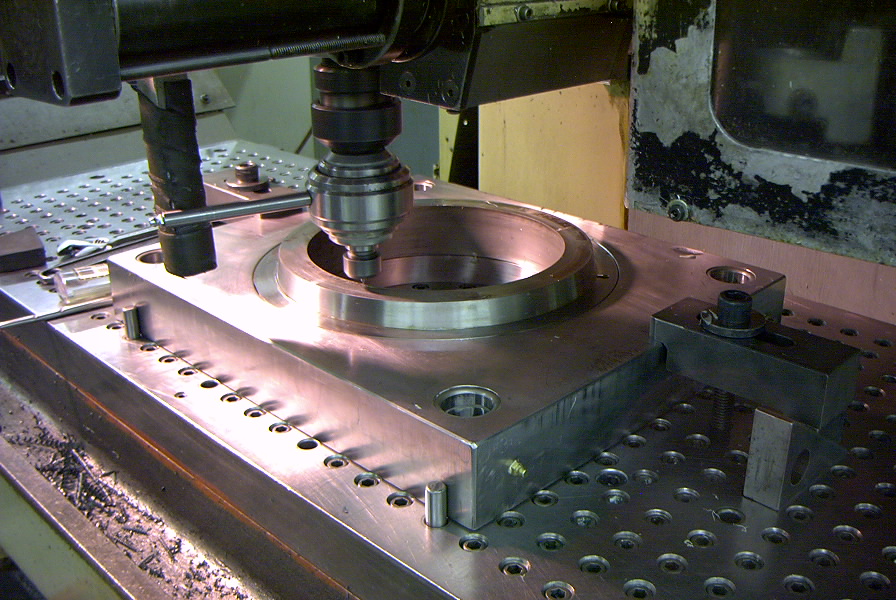

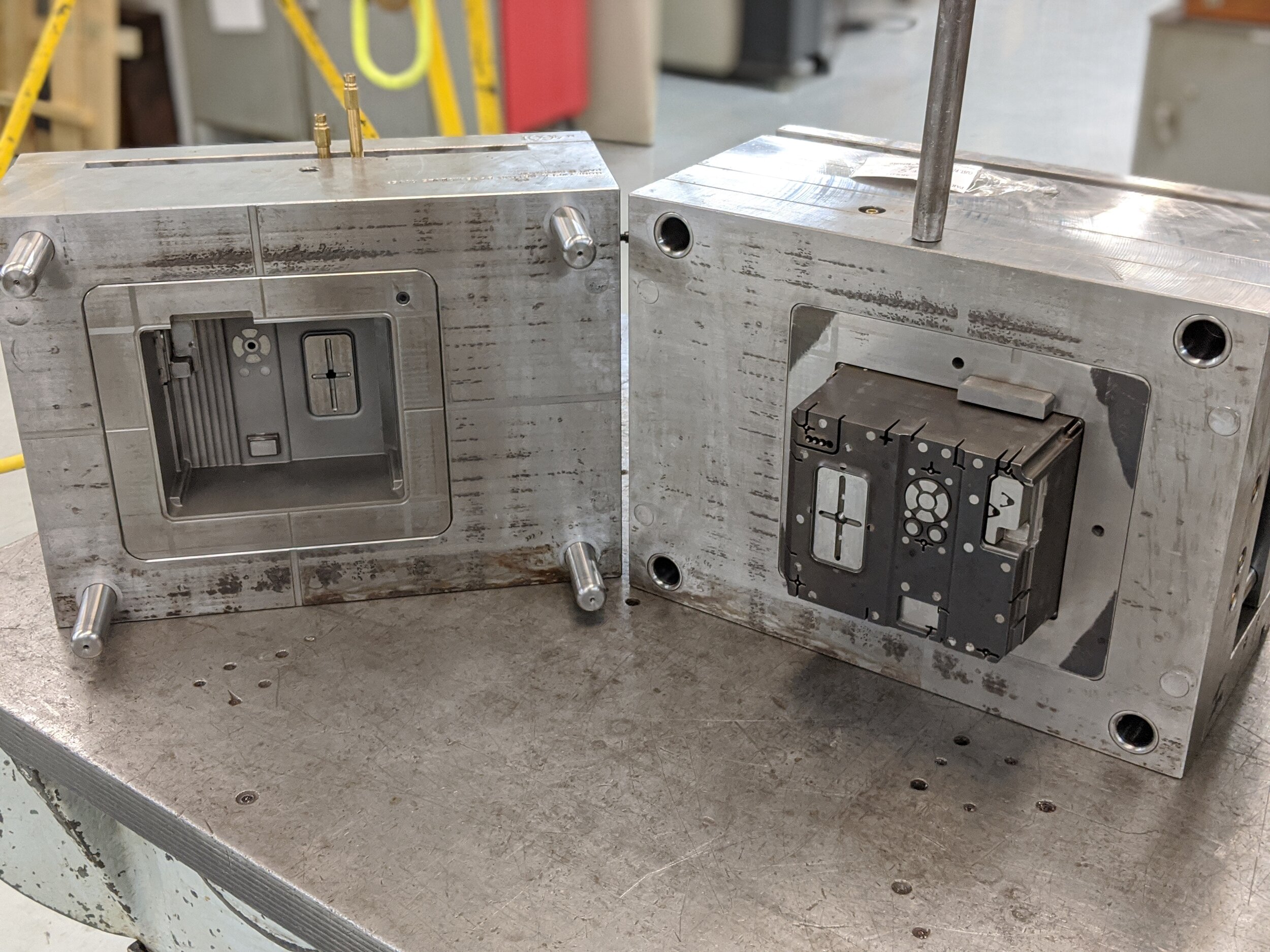

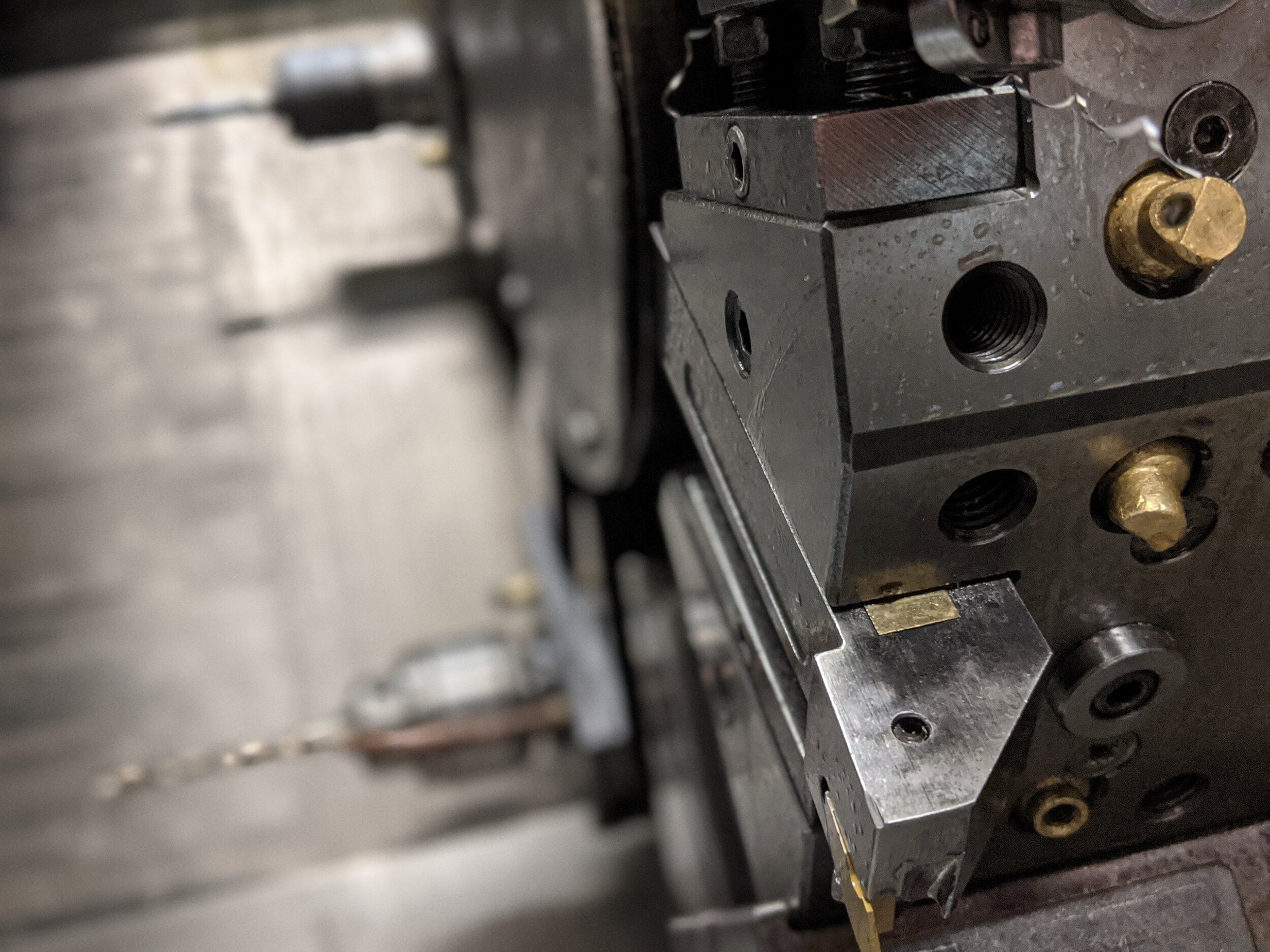

Injection Mold and Stamping Die Production

Many years of experience in tool-building; our average toolmaker has over 25 years of experience in the trade

Building World-Class tools, designed for years of quality production

Use of CNC lathes, CNC machining center, CNC EDM, Wire EDM

Conventional mills, boring machines, grinders

Complete in-house mold finishing including texturing, polishing, lettering and logo imprinting

Building mold types including:

Hot /Insulated runner molds

Stack molds

Unscrewing molds

Insert molds

Cam / Hydraulic core pull molds

Building die types including:

Compound dies

Progressive dies

Blank /pierce /cutoff dies