Injection Molding

Process Capabilities

(20) Injection molding presses

Presses range in size from 55 to 880 tons

Environmentally controlled molding facility with 24 hour operation

Shot sizes up to 76 ounces of plastic

Mold design, build, and production is in same facility for ideal service of part and tool changes

Cavitation from one to 96 cavities per mold

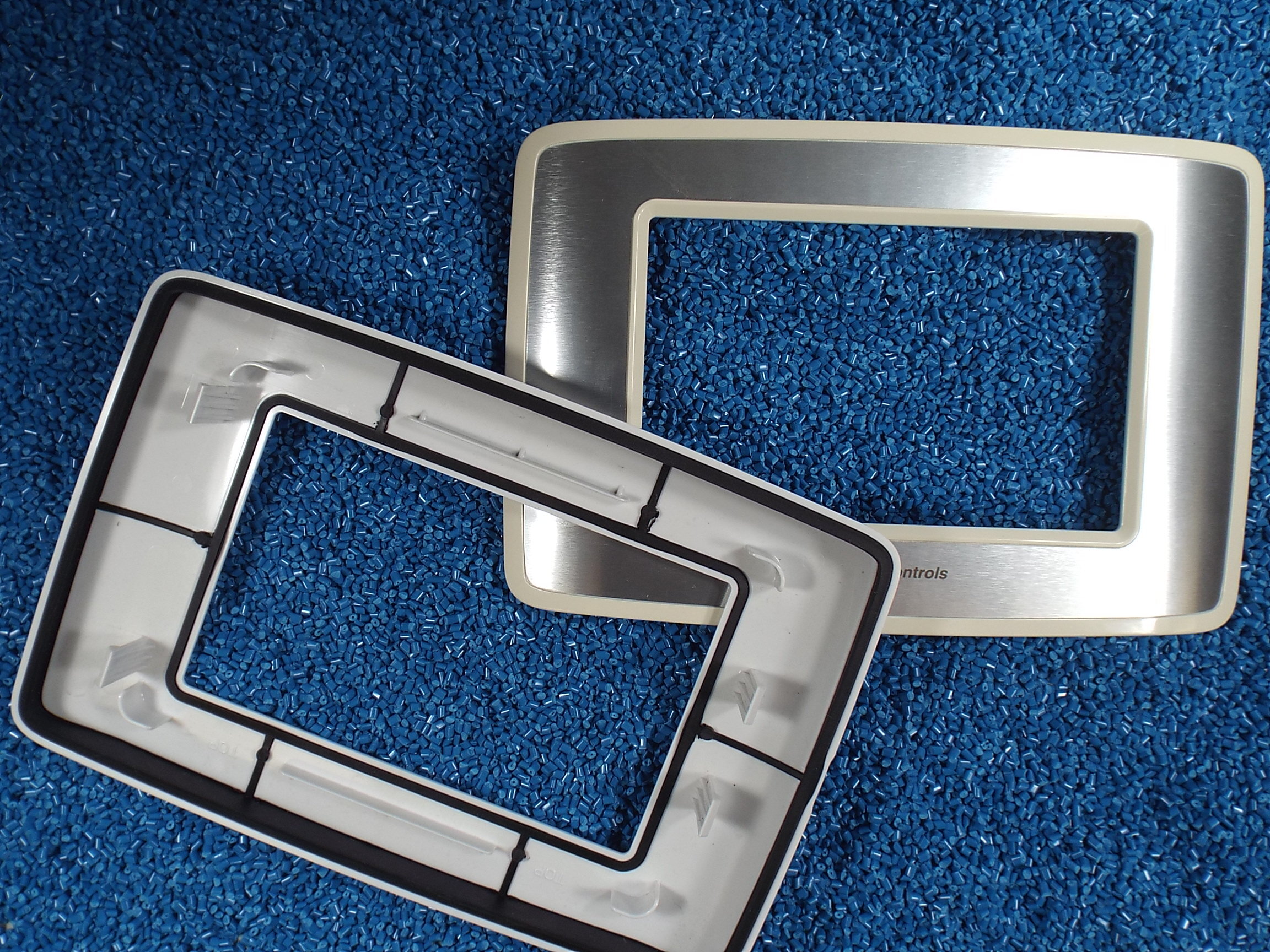

Process hot /insulated runner, stack, unscrewing, insert, and cam /hydraulic core pull molds

In-house 3D Printing capabilities

Materials Molded

Commercial grades of polypropylene, polyethylene, nylon, polystyrene, and ABS

Engineering resins including polycarbonate, polyester, urethane, PVC, acrylic, acetal, PPO, PBT, and TPR

Glass, mineral, foam, and Teflon filled materials

High temperature (oil-cooled) molding resins

Protein and starch based thermoplastic resins

All colors are available

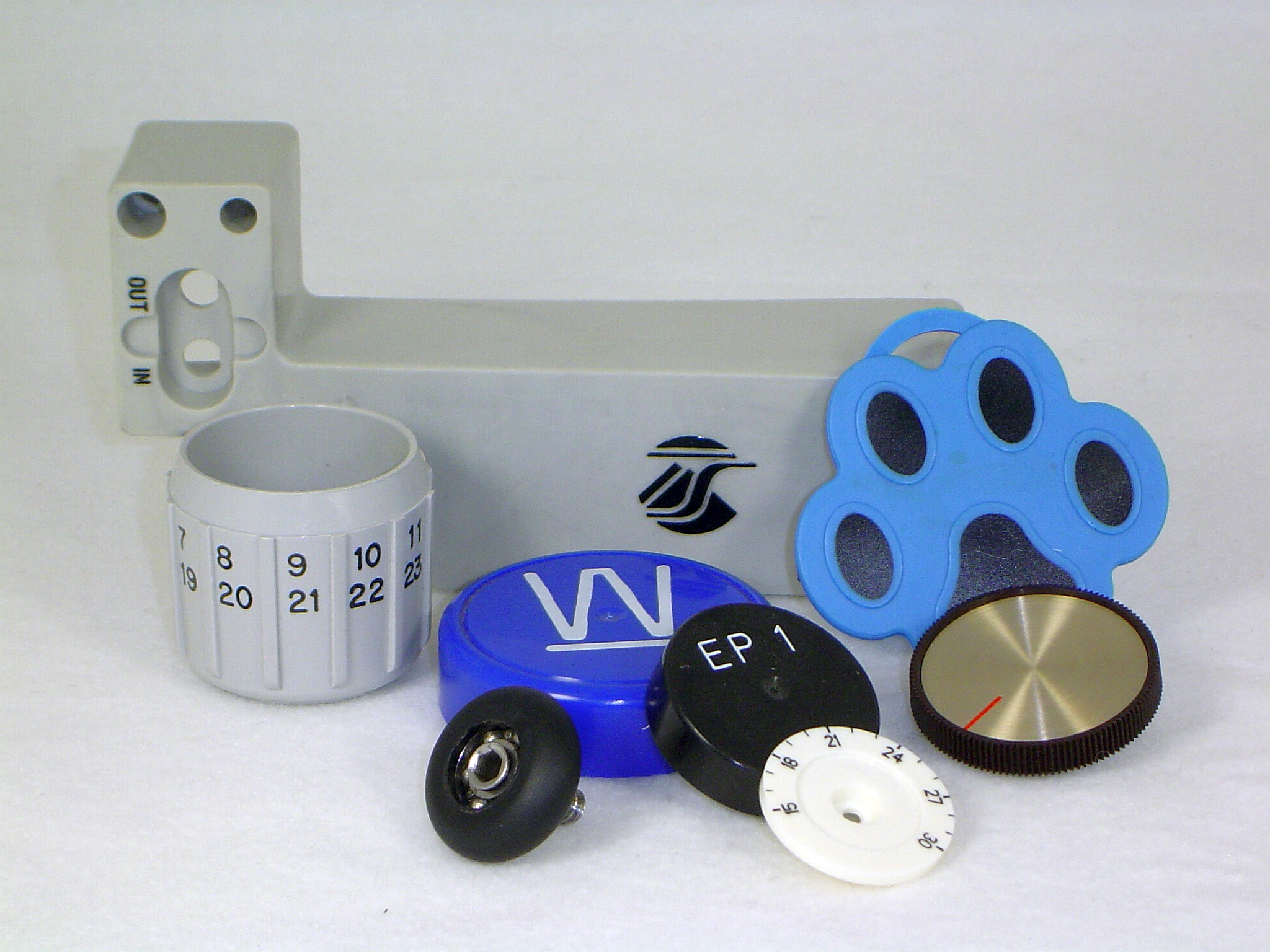

Value Added Secondary Operations

Hot stamping, painting, and silk screening

Sonic welding and adhesive bonding

Pad printing

Drilling, tapping, and secondary CNC machining

Assembly of molded /stamped parts to a finished product

Special packaging for commercial or retail

Customers /Industries Served

Serving small businesses and fortune 500 companies in the U.S. and around the world

Products for industrial and home controls, communication, agriculture, consumer products, health care, transportation, commercial equipment and many other industries

Providing quality service to surpass our customers needs in a value-minded manner is Dimatic's primary mission