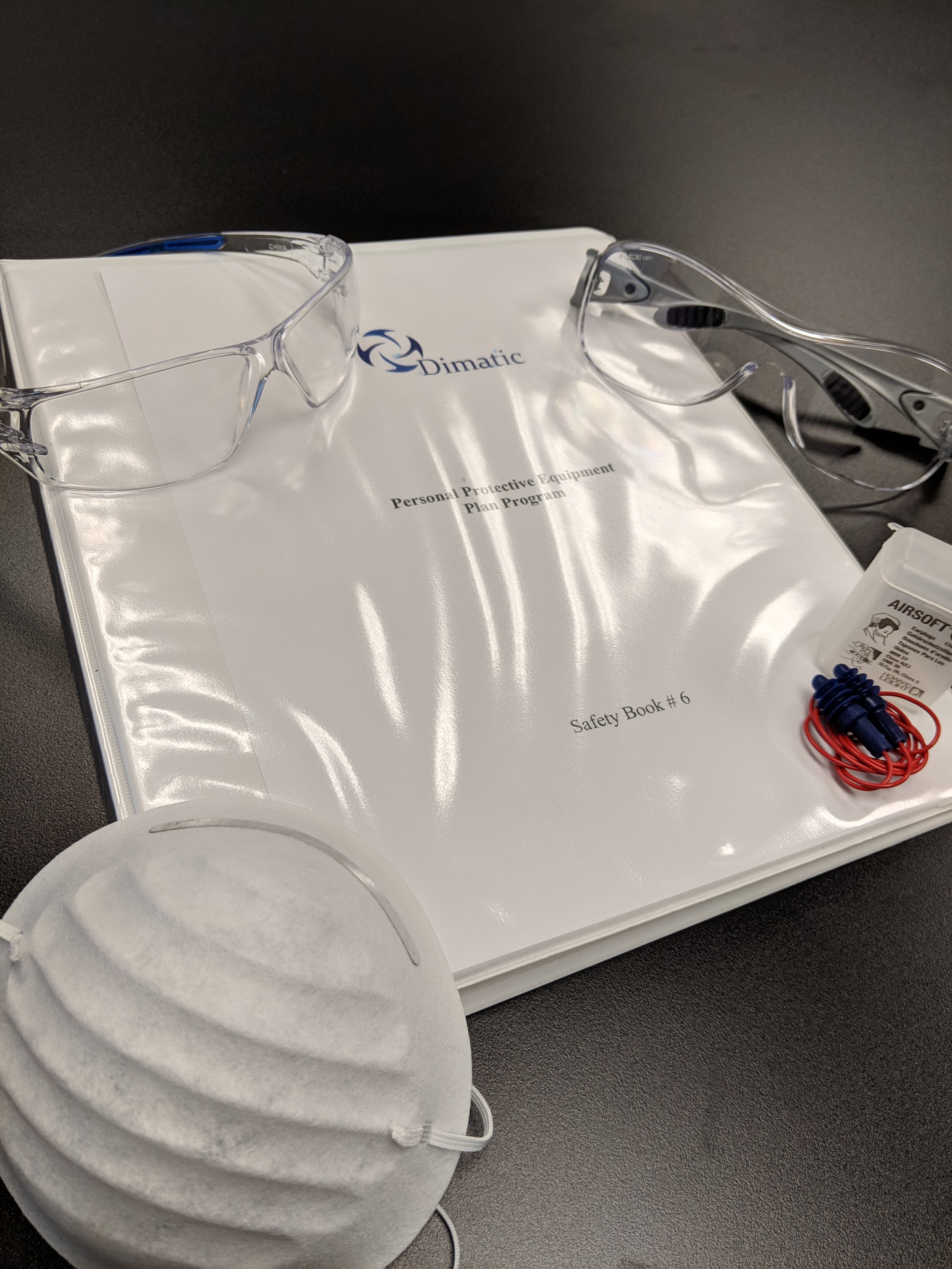

At Dimatic, safety is a top priority, and this can be seen throughout our company. While we work hard on a daily basis to maintain a safe environment for all employees and visitors, we believe that safety is an area that we must continually improve upon . Dimatic has several programs in place to ensure we are appropriately preventing accidents while also ensuring our employees can all respond in case an emergency would arise. These programs range from Hazardous Communications and SDS (Safety Data Sheet) Procedures to Emergency Evacuation Procedures, Forklift Safety, and Lockout-Tag out Procedures. Our safety committee meets on a recurring basis to review these procedures, respond to employee requests, and help ensure all employees can work in a safe environment.

Last week, we held a company-wide gathering for our annual plant safety meeting. At this event, Dimatic leadership reviewed the different procedures we have in place, discussed best practices, answered questions, and took recommendations for improving our safety programs. Following this gathering, all employees were quizzed over the policies and the employees receiving the highest scores were awarded with gift cards.

Dimatic employees have shown their dedication to a safe working environment by working 687 straight days without a lost time accident. We are well on the way to topping our previous record of 2093 days. By continually reviewing our safety policies and ensuring all employees are properly educated, Dimatic is dedicated to providing all employees with a safe environment.