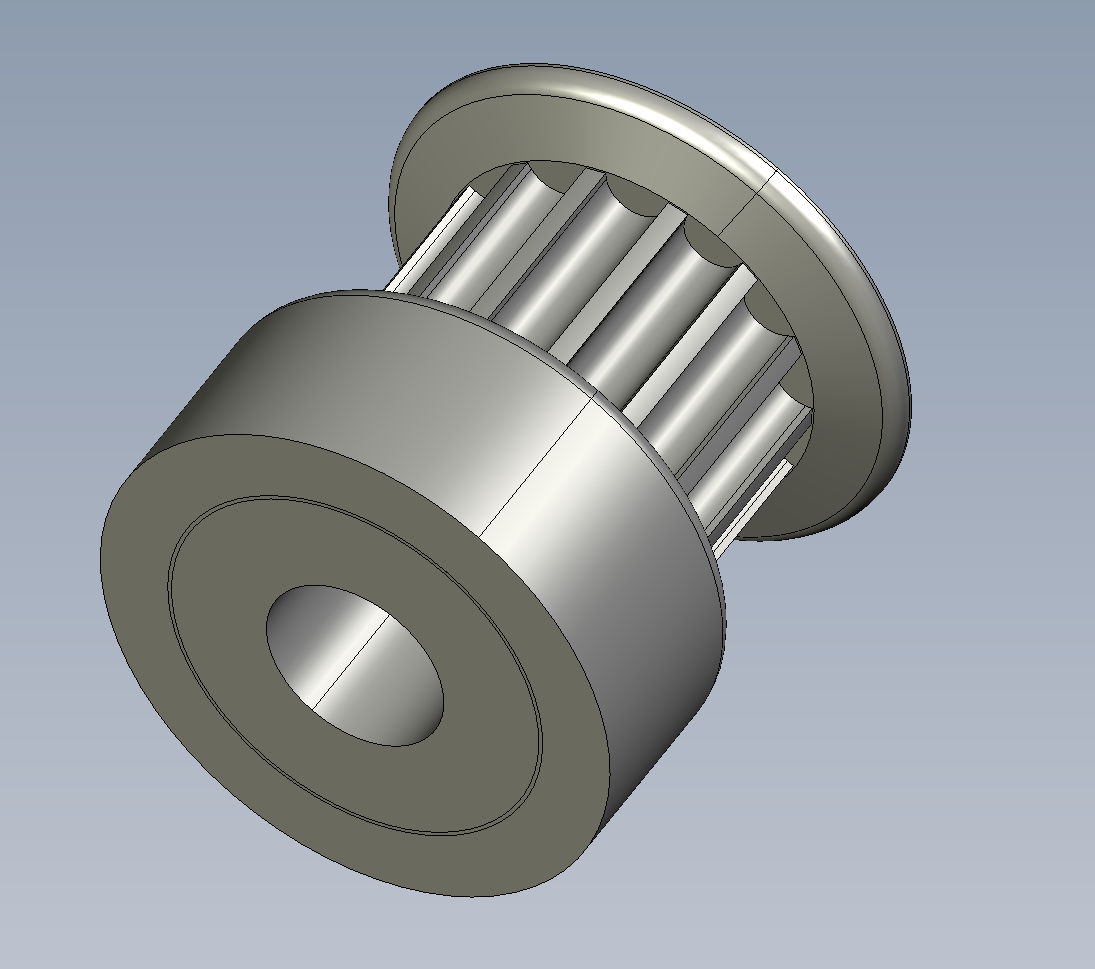

At Dimatic, we work on a vast array of project, many of which utilize more than one of our manufacturing capabilities. Once such project was a timing belt pulley we recently built for a client. This small, high precision part required work within our molding, tooling, and assembly departments.

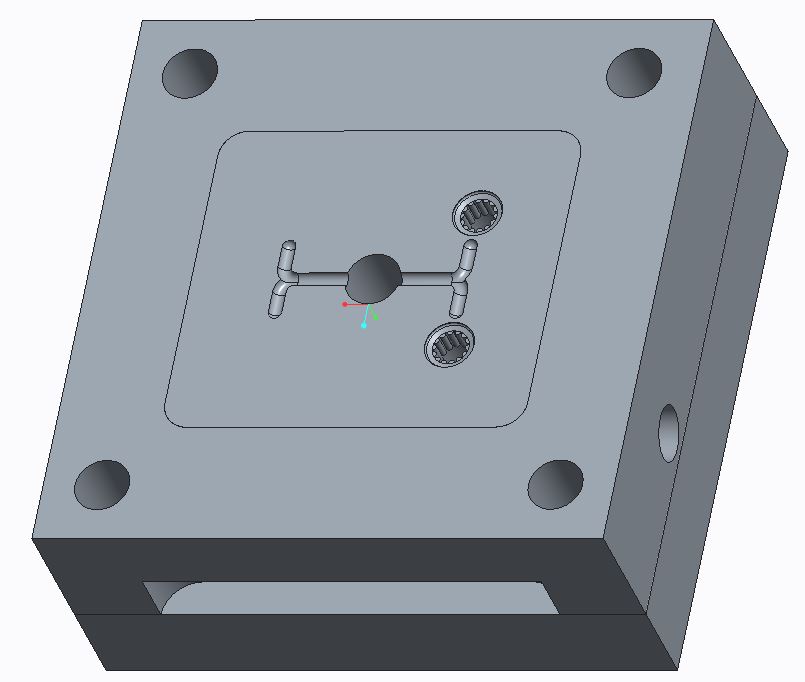

After designing and building the mold in-house, the first process in creating this part is a process called over-molding. In this injection molding process, a single part is created from two or more materials. The first material, in this case the aluminum hub, is partially covered during the injection molding process with the injected plastic. For this pulley, an aluminum hub is placed into the mold before a cycle is ran. After the cycle, in which a glass-filled polycarbonate fills the remaining cavity within the mold, a single part falls out which is the combination of the plastic and aluminum.

Following molding, the part is taken into our assembly area where it is drilled and tapped in order to add set-screws to the part.

Finally, the part goes through a process called “Sonic Welding”. This is a process, commonly used for welding together plastics, which uses high-frequency mechanical motion to generate heat to join together two thermoplastics. This process forms a molecular bond between parts. In regards to the pulley, sonic welding is done to weld the flange onto the body of the pulley and finish the part.

By having the capabilities to complete all of these steps in-house, we were able to save our client money and time while providing them with high quality parts to fit their needs. Dimatic’s versatility and diverse abilities met the challenge of this project and provided a high-quality part to its client.